Case Studies

HOCKLEY BOTTOM

The ten-and-a-half-tonne residential project was an incredible test for our team.

Many factors lead to this being a highlight project for Steelo including six dual-radius curved beams, the longest of which was nine meters in length. We worked closely with Vision Developments South Ltd. to make sure the client’s needs were met. We also liaised with Splendid Effect Ltd.

The steel erection team selected for this project, to make sure they were on-site and ready to build the structure as soon as the steel was on site.

“Steel Ltd recently completed a project at Hockleys Well Street, Burghclere, RG20 9NH. We have worked closely with Steelo on this project, and I am pleased to share our positive experience with their team Throughout the project, Steelo Ltd demonstrated a high level of professionalism, expertise, and commitment. Their work on the structural elements was particularly impressive, with all tasks completed to an exceptionally high standard and within the agreed timeframe. Their attention to detail and ability to meet our specific requirements ensured that the project ran smoothly and efficiently from start to finish. Communication with Steelo Ltd was clear and consistent, and any challenges that arose were handled promptly and effectively. Their team was always responsive and willing to go the extra mile to ensure our satisfaction. I would not hesitate to recommend Steel Ltd for similar projects and would be happy to work with them again in the future”

L. M – Contracts Manager

Vision Development South LTD

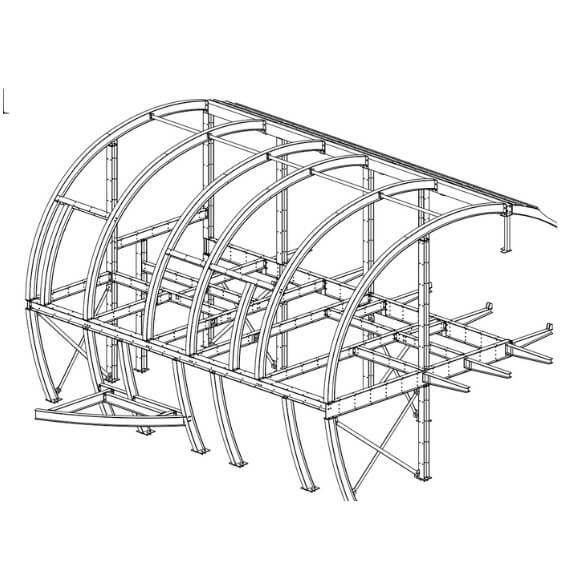

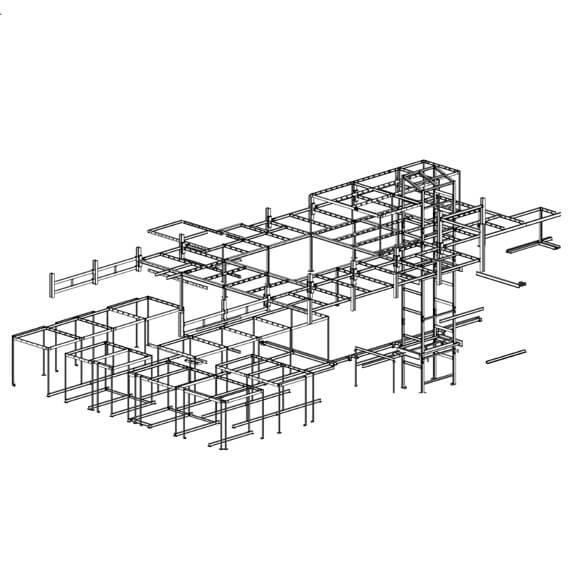

KENSINGTON ROOF GARDENS

For this project, we delivered 60 tonnes of structural steel fabrication for Arcacia Limited at the Kensington Roof Gardens. The complex steel framework,was meticulously designed and fabricated for a major construction endeavor.

This structure highlights Steel’s expertise in managing intricate designs, incorporating challenging elements such as dual-radius curved beams and numerous connection points that demanded careful planning and precise execution.

“We have worked with Steelo for many years on both large and small projects. They have always been excellent to deal with both in terms of design coordination but also the efficiency and speed at which the steel is delivered to us. The projects have varied in complexity. The Roof Gardens was by far the most complicated thus far in terms of both engineering but also logistics and split deliveries. Steelo dealt with all of this superbly. It is fair to say that Arcacia have never needed to look tor another supplier”

Emma Fyffe

Project CoOrdinator

Arcacia Consulting Ltd

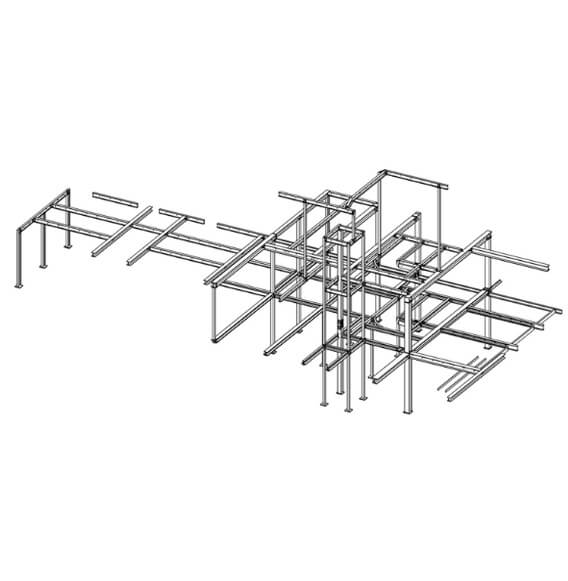

THE LANE

The nearly 30-tonne steel project was a challenging and exciting undertaking for our team. The structure consisted entirely of straight beams, including various sizes with weights ranging from 259 kg to 2803 kg and lengths up to 19.15 meters.

This project posed a unique challenge for the contractor due to the requirement to maintain the existing façade of the building located close to Abbey Road Studios.

“I can confidently say that Steel are one of the best fabricators on the market. We’ve worked with Steelo on numerous projects and they have always delivered exceptional results. Most recently, they were instrumental in completing vet another successful project, providina precise structural steel fabrications that were of the highest qualitv

Their ability to deliver on time, has been crucial in helping us maintain our project schedules. The prompt delivery of materials to site allows us to plan and execute our projects smoothly and without any delays. Steel’s attention to detail and precision in fabrication always ensures that all components fit perfectly, which reduces our installation time and helps to keep everything on track.

1 highly recommend Steelo to anyone in need of a trustworthy and dependable steel fabricator”

Gregory Horodenski

Smart Conversion Ltd

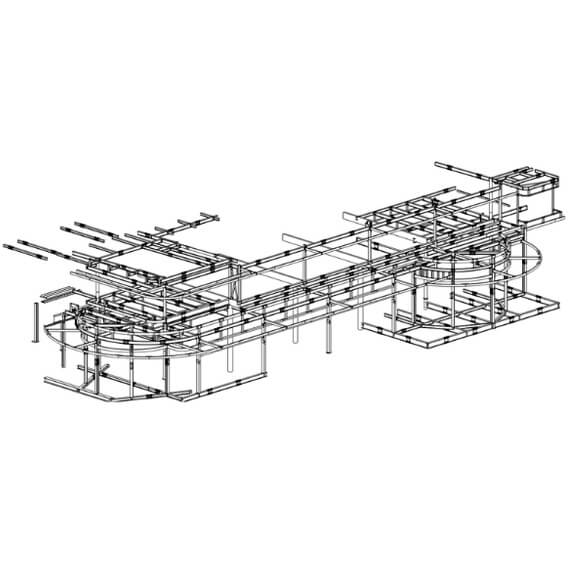

BBC - EARLSTREE

This nearly 50-tonne steel project posed a considerable challenge for our team, requiring fabrication in stages and erection by our mobile welding team. The structure comprised a variety of steel sections, including SHS, UC, UB, PFC, and RHS beams, with the heaviest component weighing 7,849 kg and measuring over 335 meters in length. This project involved fabricating steel structures that allowed the client to create mezzanine floors within a film studio. The aim was to divide a single floor into two usable levels, as the ceiling height was sufficient to accommodate the additional space. We worked closely with Henny Ltd. to ensure that the client’s requirements were fully met.

To streamline the process, our in-house systems ensured the steel fabrication was carried out with precision and within the necessary tolerances.